How can applying data modeling to Building Automation System database make an operator’s job easier. Four common ways:

- User Interface

- Histories

- Program Logic

- Equipment Summaries

Program Logic – data modeling example “programOn” tag

Programming logic based on tags is extremely powerful. Creating sequence of operations, creating system “rollup” points for minimum, maximum, totals, alarms, etc.

The great thing about programs based on tags is one program can run on 1,000 pieces of equipment. The “bad” thing about programs based on tags is one program can run on 1,000 pieces of equipment. Great care needs to be used when defining a program to make sure it is only running on the intended equipment.

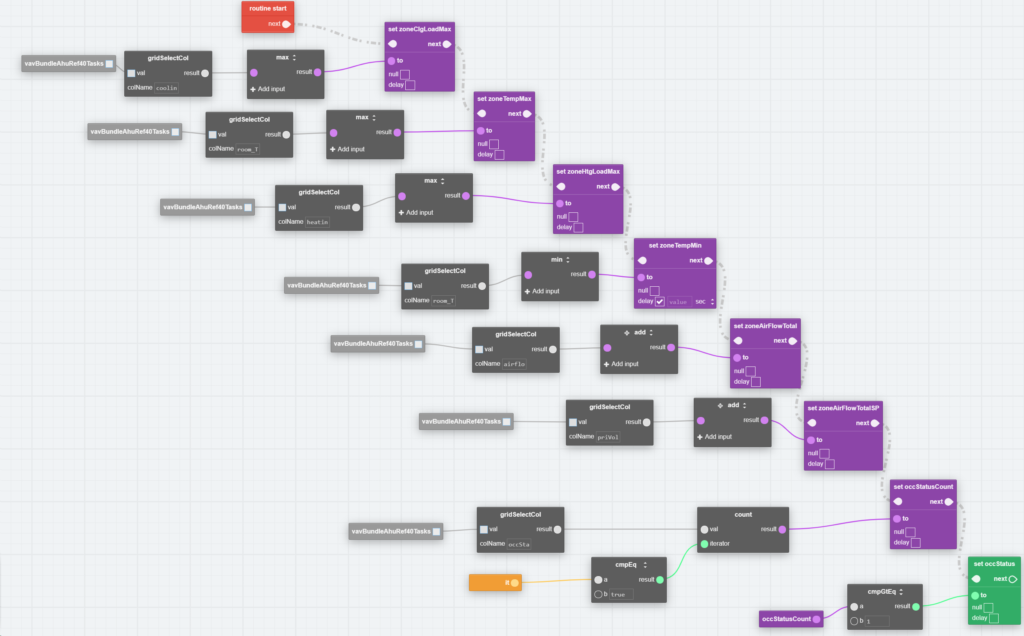

An example of AHU VAV rollup points. The program runs on any AHU serving VAV boxes. The program calculates minimum, maximum, and totals for air flow, cooling load, heating load, and room temperature. It also counts the number VAVs are in the occupied mode served by a specific AHU.

Fin|Stack and Haystack tagging, you can define tags once and realize value in multiple ways. again. Whether its a simple alarm logic or more complex sequence of operation, the programOn tag will replicate the logic program to as many similar pieces of equipment as you need.

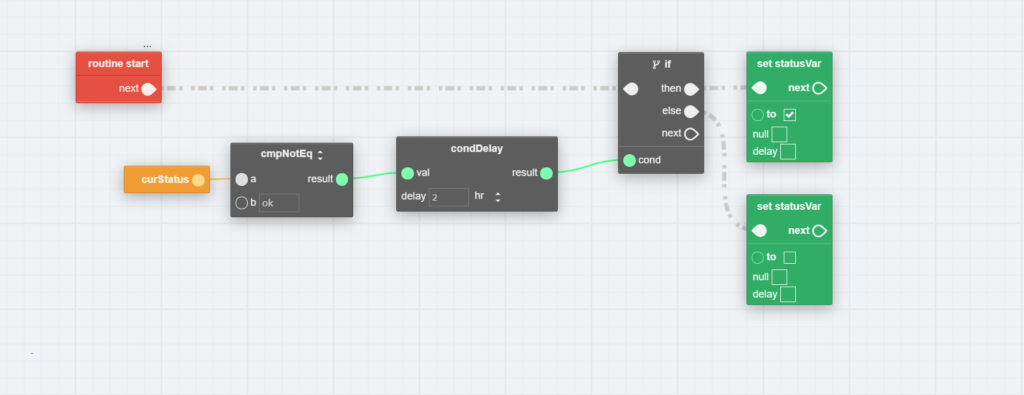

Logic usually runs on equipment but it can run on points for greater functionality. For instance, logic to alert the operator when a connected device is offline. The programOn tag for the logic – “point and allowProgram and deviceStatus.” Any point with the “deviceStatus and allowProgram” tags will be monitored. If the “curStatus” tag value does not equal “ok” then the point is offline and the logic will create an alarm to alert the BAS operator of the issue.

These are just two simple examples. For more information contact us here.